If you want to give a little gift packaging to a new product, this is where you can find your little boxes. Alternatively, a selection of these packages could be an ideal way of packaging your products for sale if you are a small item retailer or wholesaler. Also, for medium or large boxes, you will find GleePackaging is also a good choice. Even extra large gift boxes are not a problem.

- Home

- Gift

Bulk Custom Luxury Gift Box Manufacturer

Custom luxury Presentation gift box with brand logo allows retailers to attract their potential customers as these packages are customized and designed in such a way that they contain catchy graphics, high printing quality and visual quality.

You can trust GleePackaging to deliver premium bulk luxury gift boxes you’ll be proud to bear your brand. Need help choosing the best custom luxury gift boxes for your business? Not sure how to set up your artwork? We’re here to help you.

Luxury Gift Boxes By Type

We provide many styles for luxury gift box, including top-tuck, 2-piece lock corner, and separate lid and base box. The gift boxes range from folding chipboard to rigid set-up models in a wide variety of colors. All of our fancy gift boxes are assembled in China with environmentally friendly recycled paperboard and water-based inks.

Luxury Gift Boxes By Use

Our custom luxury gift boxes can be used to spice up any gift, like wine, candle, jewelry, cosmetic, flowers, etc. and come in so many sizes that there is no gift too big or too small. Lined with our decorated or printed paper shreds and finished with a pretty plum colored ribbon bow, you’ll be able to give a perfect luxury packaging to your products.

Luxury Gift Boxes By Size

Luxury Gift Boxes By Color

Pick what you need for the perfect presentation from our wide range of specialty colored gift boxes. Our lines consist of one and two-piece gift boxes; bright, wooden, fluted and crafted boxes and many others. Colors like black, white, pink, red and blue gift boxes with matching fixed ribbon ties are a perfect luxury packaging solution for small gifts.

The Master Luxury Gift Boxes Buyer Guide

Packaging is one of those topics that almost everybody knows a bit about. These days we undoubtedly need a lot of branded packagings to deliver products. In addition to look for the best qualified manufacturers in China, you might need to know more, about products, and about supply chain.

We understand. That’s why we want to share some of our experiences with you in order to make your luxury gift boxes experience perfect.

We Take Care Your Gift Boxes

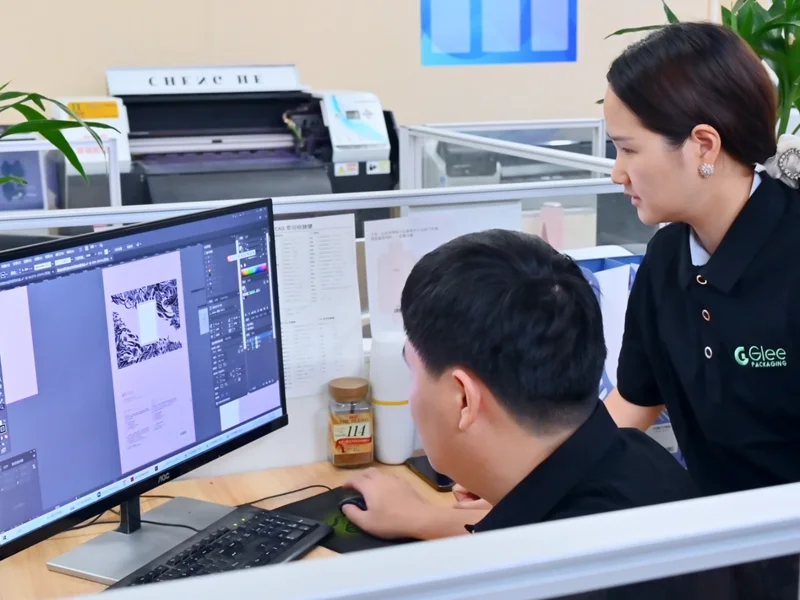

In-house Manufacturing

As a GleePackaging customer you’ll enjoy the many advantages of dealing direct with a specialist luxury gift box manufacturer; including design expertise, cost savings and reduced lead times.

Latest Printing Technologies

Our printing and customization experts are equipped with the latest technologies such as offset, screen, and digital printing technologies that allow them to provide desired printing quality to our clients.

Wide Range of Design choices

We add multiple customization features including window cutouts, perforation, gold and silver foiling, high-end silk and velvety coating materials, and most importantly embossed branding elements that make these packages outstanding to allure customers.

Eco-friendly Packages

We know the importance of green packaging for environmental health and human life; in this regard, we use high quality yet recyclable and reusable materials like cardboard and Kraft paper stocks and help our clients to accomplish environment-friendly business status.

Your Ultimate Gift Packaging Manufacturer

Tell us a little about what you need and our friendly staff can get your next luxury gift box project started right.

I need a structural design collaborator

Packaging engineers can create a die-line for your gift box packaging, whether it is from a scratch or specifications.

I have a product, service or idea that needs a package

Whether you need 10 rigid boxes or 10 million, we are the gift box factory you’re looking for.

I have specs and need a high-quality production partner

We have the knowledge, equipment, and expertise necessary to advice for your packaging.

Request a Quote & Get Samples

GleePackaging premium box & printed packaging manufacturing is one of the strongest points of contact between your boxes and your market. Contact us today to discuss your project!

The Master Note

How Custom Luxury Gift Box Packaging Boosts Your Brand?

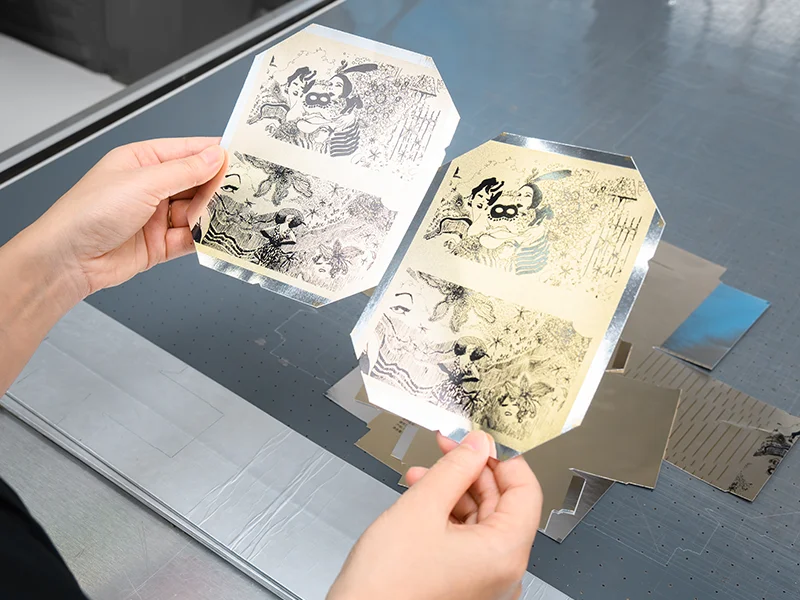

Starting from scanning to assembling, printing, and lamination, all steps need 100% perfection to create a great aesthetic view of the custom luxury gift box. Some of our printing specialties include: embossing, debossing, foil stamping, specialized coatings, special inks, labeling, glossy/matte laminating and more.

Internal fitments like paper shreds, foam inserts, internal trays, and decorating materials such as ribbons are also customized. We determine the best gift box production process for the job once your design has been presented to us.

Choosing the right custom box for your wholesale business is an important decision, but not one that should cause you too much anxiety. With hundreds of styles, sizes and materials to choose from, you are guaranteed to find options at GleePackaging that will work great for your business or event.

You can order a variety of retail gift box sizes in bulk at wholesale price and have them customized uniquely to meet your wholesale packaging needs.While getting a gift box designed you need to make sure that the material used is of best quality and the design perfectly complements the gift.

We offer various packaging printing for your luxury gift boxes. The finishing options we offer include embossing, debossing, silver and gold foiling. Stock options are unlimited with velvet, silk interior and card stock linen. You can have matte or glossy finishing as well.

We use offset, screen and digital printing processes to offer you handmade high end packaging products. We use finest inks and materials to give you best of quality for your gift boxes. Customized luxury packaging is our expertise, therefore we make sure that all the boxes we print are according to our client needs and liking.

You also can keep an inventory of gift boxes with lids that have your logo hot stamped on top, while you might have a variety of stock gift boxes on hand as well that you prefer to wrap with gift wrap and a custom logo label instead.

When it comes to outfitting your retail shop with boxes for shipping or packaging, we offer a great selection of custom and stock products at competitive wholesale prices.

When manufacturing in China it is imperative to regularly visit factories and keep on top of all aspects of production. This is often a difficult task when you’re located halfway across the world. To make things easier, let’s take a lesson on gift box manufacturing that doesn’t require a plane ticket.

Step One: For luxury box packaging manufacturer, the first process is cardboard cutting – to cut the large piece of cardboard down into a smaller piece of cardboard. This process is repeated until the desired size of the cardboard is achieved. After this, the cardboard begins it’s the journey into die cutting.

Step Two: Die cutting is where the design is cut out using pressure. As seen in this video, the worker moves one piece into the die while pulling the die cut piece out at the same time. Meanwhile, the machine keeps moving. This process can be slowed down for different materials, for example, when die cutting PU the machine is slowed due to the PU having less rigidity and therefore being more difficult to place accurately.

Step Three: The printing process is started by creating the desired color of paper and printing a design onto the colored paper. This process needs to ensure that the paper is the correct colour on both sides. The paper is fed through print rollers to apply the logo smoothly.

Step Four: It is then critical to allow the print to dry for the correct amount of time due to the stress put on the print during the following steps.

Lamination is when the paper is passed through rollers and attached to lamination film that is also being fed through. This results in the paper not only having a glossy finish but also having increased strength.

Step Five: Following lamination, the laminated paper is now passed through another machine which coats the inside with glue. Following this, the die cut cardboard is applied to the paper. As seen below, the final process is to smooth the sides and create the finished foldable piece ready for final assembly.

Step Six: The required pieces are then glued inside and shaped for assembly into the finished box.

Step Seven: The final production step is to allow the box to dry thoroughly prior to shipment to the client.

Both the design and the functionality of packaging matters to retailers. The way items are packed in a gift set should highlight important products, ensuring visibility through things like window boxes and thermoform risers. At the same time, merchandise needs to be packaged securely to protect it from damage or displacement in the gift box during transportation.

Products packaged in a gift box can also make life easier for retailers by improving efficiency of tasks like stocking and checkout. That includes the ability to quickly and easily set up retail displays and fill store shelves with your brand’s gift sets.

The retail advantages:

- Increasing Consumer Loyalty

- Premium Packaging and Repeat Purchases

- Improves Word-of-Mouth Marketing

- Importance for Luxury Brands

- Choosing the Right Design

GleePackaging can provide expertise in a wide variety of areas. From coming up with a concept for premium package design to picking the best material and graphics for the package all the way through shipping and fulfillment … we have the experience your brand needs to turn gift sets for special occasions into a success.

In addition to print and design capabilities, we offer end-to-end solutions for retail product packaging as well as shipping solutions and supply chain solutions.

Contact us today to find out more about how we can help.

With over 10 years of experience and knowledge in the custom luxury gift box printing industry, we pride ourselves on our product results and excellent customer service. Not only do we use the best packaging materials to produce your boxes, but we also have a large state-of-the-art production facility with a number of highly dedicated and experienced employees, equipped with a full range of high-quality machines that are sufficient to meet the needs of multiple parties in all processes. Our machines can not only produce the simplest designs, but even print and produce detailed and complex packaging, as we offer CMYK full color printing to ensure that your logo and graphics are printed with enough delicacy. This means that your gift box will end up with a unique look and the best brand feeling. Brand owners, creative designers and retail clients can now also enjoy competitive pricing and one-on-one service.

We understand how important a company’s product branding is, and the first thing what customers notice is the packaging, GleePackaging provides custom printed gift boxes from small to large for customers worldwide. As for the printing of various materials, we have a wide range of printing techniques to meet any customer’s needs, producing boxes that meet 100% of all customer design requirements. Our customer service is simple and quick, ensuring that anyone can explain their artwork and graphics clearly, and we offer free samples. In addition, GleePackaging supports eco-friendly and green luxury gift box packaging. We only source environmentally friendly forest wood to produce our luxury gift boxes, thereby taking responsibility for the environment as a business. In addition, our company and production facilities meet a number of international environmental standards. Contact us, wholesale your custom gift boxes orders, and boom!

Share Your Concerns for A New Packaging Solution

Packaged to make Perfect. GleePackaging is here to help you with a solution that connects your brand to a broader market.