- Home

- Corrugated Boxes

Bulk Custom Corrugated Box Manufacturer

Top Tips for Corrugated Boxes

- Best for storage and delivering, opt for multi-layer corrugated boxes for heavy-duty work.

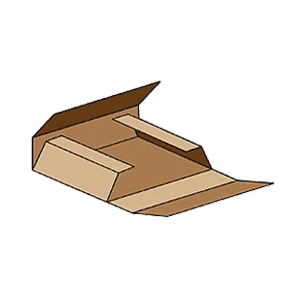

- Use the self-locking corrugated box to achieve minimal use of adhesive.

- The one-piece corrugated box is perfect for easy assembly.

- Made from recycled materials and are 100% recyclable.

Corrugared Box Styles

.webp)

Types of Corrugated

Printing Option

Special Finishes

Can’t find what you’re looking for? Contact our elites.

Corrugated to Get Your Goods Covered.

Whether you are seeking a stronger solution to protect your goods during shipping/delivery, or a simpler way to organize your warehouse, here at Gleepackaging, you will get exactly the right boxes for you.

Heavy Duty

Thick, layered, choose extra hard corrugated boxes for heavy-duty packaging tasks.

Grocery & Retail

Easy way to box your products, organize your goods and shelves.

Storage

Your space-saving solution, while strong enough to withstand challenge of time.

The Advantages of Custom Printed Corrugated Boxes

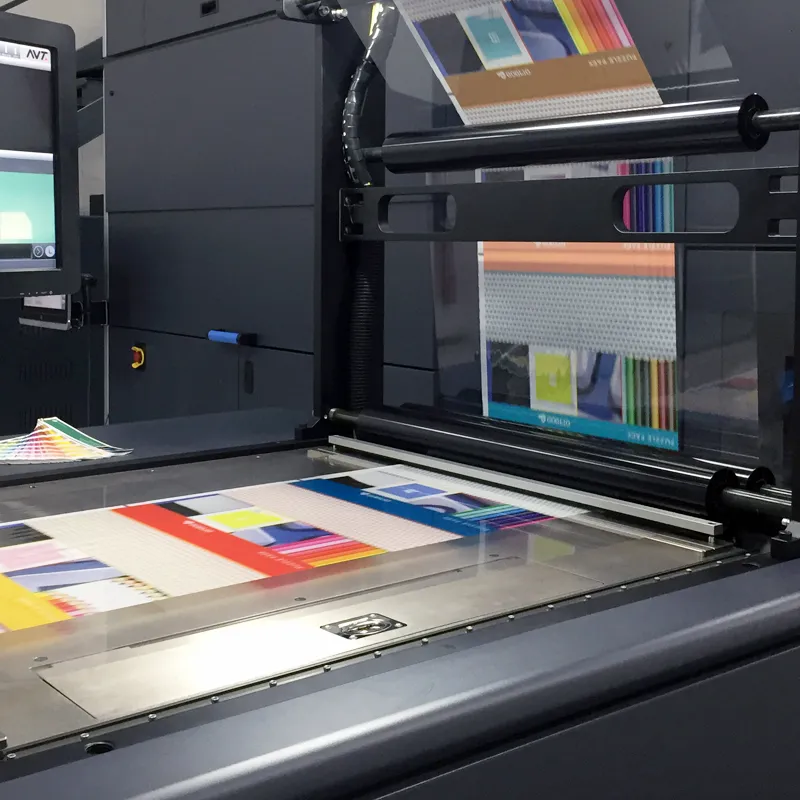

Digital Printing

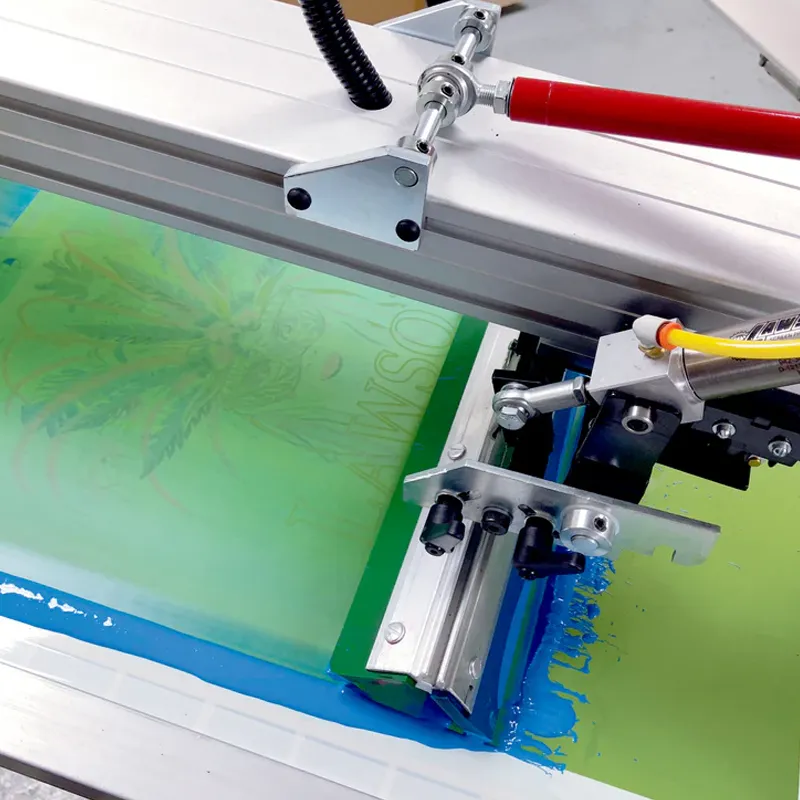

Screen Printing

When you need special effects and textured finishes, screen printing delivers. With ink layers up to 2-3 times thicker than other methods, this technique is perfect for premium packaging that requires a tactile, high-impact presentation.

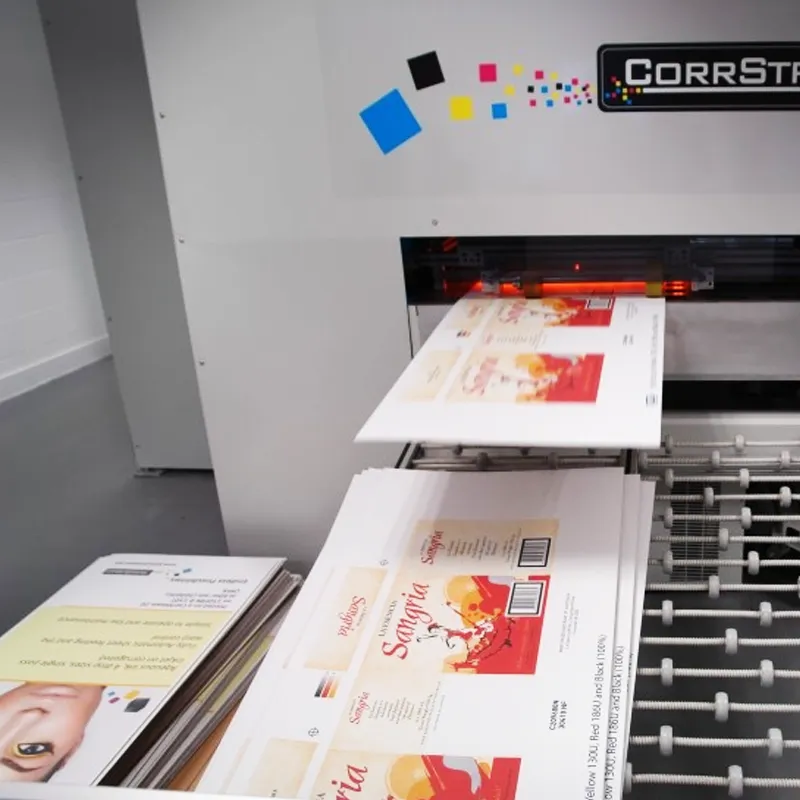

Flexographic Printing

Achieve cost-effective, high-speed production with flexographic printing, the preferred choice for large-volume packaging. It is ideal for food and beverage packaging, offering efficiency without compromising quality, using environmentally friendly water-based or UV inks.

Soy-based Ink

Further cut your brand’s carbon footprint by using 100% eco-friendly soy-based paint. This paint is made of soybean oil and pigment, making it harmless, food-safe, and totally biodegradable.

Soy-based ink delivers vibrant colors, matching the performance of traditional inks, so there’s no need to worry about quality.

Reduce your brand’s carbon footprint by opting for 100% eco-friendly soy-based ink. Made from soybean oil and natural pigments, this ink is non-toxic, food-safe, and fully biodegradable.‘

Paper Range

Recyclable face material

FSC® Certified

Carbon Balanced

Corrugated Box Recommended for Your Products

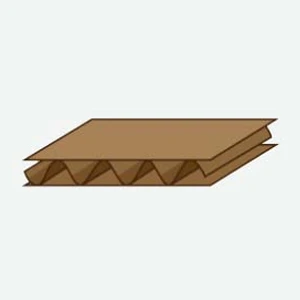

Corrugated boxes rely on the strength of their corrugated board to maintain durability and protect the contents inside. The thickness and weight of the corrugated board depend on the size of the box and the weight of the items it will hold. While it’s hard to convey the sturdiness of different corrugated materials without feeling them firsthand, here is a guide to common items and the typical board weights used for their corrugated boxes:

23 PT. TO 28 PT.

Lightweight items like clothing, soft toys generally use thinner corrugated paper, around 23-28 points.

28 PT. TO 32 PT.

Food & Cosmetics, which are generally lightweight, use 28-32 point thickness for adequate protection.

32 PT. TO 44 PT.

Depending on the size and weight, books & ornamnets use 32-44 point thickness for protection against drops and impacts.

44 PT. TO 48 PT.

Electronics need strong, durable boxes, usually around 44 points in thickness. Heavy home appliances often require 44-48 point thickness for strong protection.

Your Corrugated Boxes, All Tested to Go

Our Triple Testing Involves:

Edge Crush Test

Edge Crush Test is one of the essential tests to check the sturdiness of corrugated boxes. In the process, force is applied perpendicular to the edge of the corrugated cardboard until it buckles. The results ensure the strength and durability required to handle violent shipping, heavy loads and stack resistance.

Flat Crush Test

Flat Crush Test is similar to the Edge Crush Test. Force is applied directly on the surface area of the corrugated board until the inner flute flattens and compromises its structure. This test generally determines the compression and stacking resistance of the corrugated boxes required to carry heavy loads.

Burst Strength Test

Mullen Test (or Burst Test), is a standard industry measures that challenges the overall durability of the corrugated cardboard surface by determining the force needed to puncture the board.

A Corrugated Boxes Manufacturer

Your products first, you second, and Gleepackaging third. We are devoted to bringing the best.

Free Custom Design

You do the imagining, we do the rest. We provide engineering and designing supports to help build the most suitable boxes for your need. From structure and functions to shape and printings, we got you.

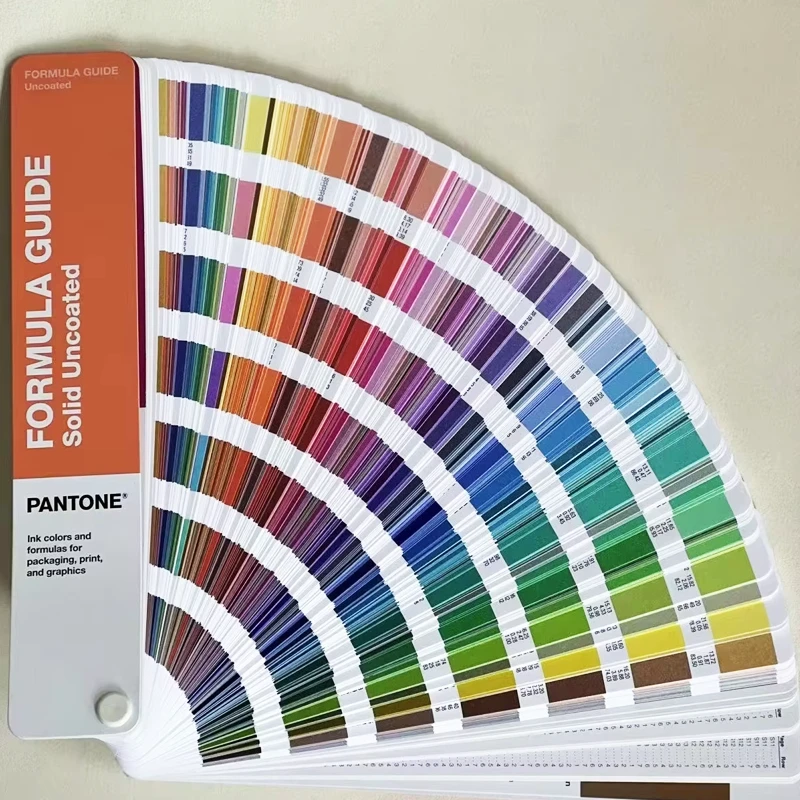

- CMYK / Pantone Color Options

- In-House Designers to Help Build the Box

One-Stop-Shop Packaging

Get the whole thing done in just one place. We help simplify your packaging solutions and provide optimized solutions to solve your existing problems for a better corrugated box.

- Tailored Plans to Save Cost with Best Effects

- Bring A Solution to Life from Scratch

Taking Responsibility

We promise to deliver the best, if it's not, we are open to feedbacks and will provide followup supports. Gleepackaging takes on full responsibilities for the products we make.

- 100% Matching Samples & Batch

- Long-term Followup Support

Share Your Concerns for A New Packaging Solution

Packaged to make Perfect. GleePackaging is here to help you with a solution that connects your brand to a broader market.