Building a good reputation is not limited to manufacturing quality products; it extends to the packaging. Decisions on the ideal packaging can be difficult, especially when you’ve narrowed down your options to two similar styles.

The tuck-end carton is a folding packaging box that’s commonly used across many industries, but it’s available in two options: straight tuck-end carton and reverse tuck-end carton.

You will need to decide which of these options is best for your product and brand. Don’t worry, in this blog, we will highlight the differences between them to help you choose the better option. But firstly, let’s describe how both tuck-end cartons look like.

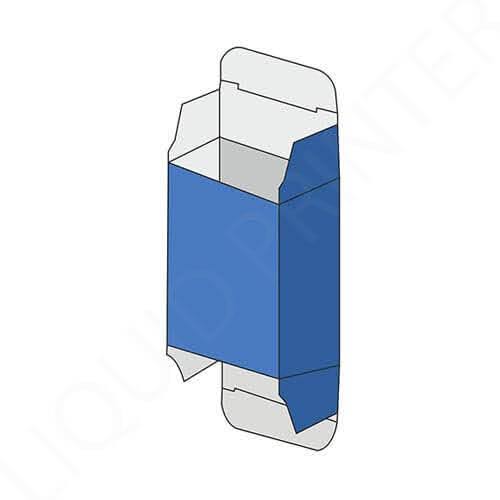

What is a Straight Tuck-end Carton?

This is the most common type used by retail brands and literally most industries around the world. It has 2 sides (a front and back with two openings). Both sides are folded in the same direction, making it easy to open and close.

Straight tuck-end cartons look great on retail or point of purchase displays. They are often preferred for their clean lines, which offers an aesthetically pleasing appearance with a secure closure.

Pros

- Simple to assemble

- They are very attractive when displayed on shelves or window displays

- Ideal for items with a focus on aesthetics

- Perfect for lightweight products like soaps, pharmaceuticals, and cosmetics

- Can be customized to any style, such as adding of hanging tab, thumb cut out, or window cut out

Cons

- Requires tight seal with tapes when packaging heavy products

- Usage of more materials because of how they are placed when printed on sheets

- Less rigid, thereby affecting the structural integrity of the packaging

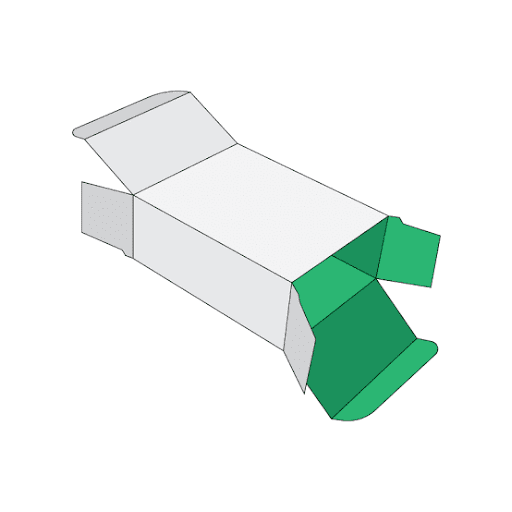

What is a Reverse Tuck-end Carton?

Reverse tuck-end carton looks almost the same way as a straight tuck-end carton. The only difference is that the 2 sides open and close in opposite directions. The top flap folds in one direction, while the bottom flap folds in the other direction. This design increases the strength of the packaging, making it ideal for carrying heavier items.

Reverse tuck-end cartons provide a sturdier structure that is suitable for packaging various product shapes and sizes. While it may be criticized for its complexity, it offers optimal functionality and product protection.

Pros

- Easy to assemble

- Requires the use of lesser materials than straight tuck-end cartons

- Better strength, making them better for heavier products like food and beverages

- Sturdy construction, which ensures the integrity of the packaging

- The design is adaptable to various product shapes and sizes

Cons

- The reverse opening mechanism tends to be complex

- Not suitable for displays on retail shelves because the reversed opening mechanism interferes with the front design of the cartons

Tuck-end vs. Reverse Tuck-end Carton

These two packaging styles are very similar, but they have a slight difference in construction. This resulted in quite a number of disparities regarding their structural firmness, application, and industry compatibility.

Structural Firmness

- Straight tuck-end cartons have less strength, hence why they are most ideal for carrying lighter items. Their construction limits them to packaging products where structural integrity is not a major concern. Also, these cartons are less rigid, which affects their ability to withstand external factors and protect the products.

- Reverse tuck-end cartons, on the other hand, offer better strength and rigidity. Due to the complex construction with flapped tucking in opposite directions, they have a more robust structure, making them ideal for carrying heavier items. Thus, these cartons are more reliable to maintain shape and protect products effectively.

Printing and Branding

- Because of the plain design of straight tuck-end cartons, they offer a larger and more continuous surface area for printing, which gives more room for detailed branding. This is advantageous for displaying intricate designs and comprehensive product information. In addition, because of the plain surface, branding elements are more visible and easily understandable when showcased on shelves.

- For reverse tuck-end cartons, the functionality of the printing and branding elements are limited because of the opposite tucking directions. This makes it difficult for shoppers to quickly grasp the information communicated through the packaging. Sometimes, they need to be turned upside down for better understanding.

Ease of Assembly

- Usually, straight tuck-end cartons are easier and faster to assemble. This makes them great for automated packaging lines, thereby enhancing efficiency during mass production.

- Whereas, reverse tuck-end cartons, because of their opposite directional tucking, makes the assembly process more difficult. Focus and keen attention is needed to ensure proper folding and closure, thus slowing down the production process.

Application

- Straight tuck-end cartons have clean and sleek appearance, which makes them the preferred option when aesthetics is of utmost importance. They offer a professional, sophisticated look, making them perfect for packaging products where visual appeal is a primary concern. Furthermore, they feature a simple opening and closing mechanism, which makes them user-friendly and suitable for items that require frequent access.

- On the other hand, reverse tuck-end cartons will take the back seat because of their complex opening and closing mechanism, which makes them unsuitable for items that require frequent access. However, their complex structure makes them versatile and adaptable to accommodate various shapes and sizes. This means that you can rely on this style for packaging a wide range of products.

Industry Compatibility

- Straight tuck-end cartons, because of their attractiveness, are used in industries where visual appeal is crucial, such as cosmetics & beauty, jewelry, and apparel packaging. They are also used for carrying electronic accessories that require a clean presentation.

- Reverse tuck-end cartons are most ideal for industries that manufacture products that require sturdy and secure packaging, as well as heavy items, such as food & beverage and candle packaging.

Which is Better?

The option to choose between straight tuck-end carton vs reverse tuck-end carton is largely dependent on your brand and product requirements.

To help you make an informed decision, here is a breakdown of when to choose straight tuck-end carton packaging, as well as when to select reverse tuck-end packaging:

When to Choose Straight Tuck-end Carton:

- If you need a sleek and eye-catching packaging that can be displayed on retail shelves or point of purchase displays.

- When you are focusing on the packaging as a branding tool.

- When you want to send samples of your products to stores and influential prospects.

- If you want to package lighter items.

- If you want to customize it with the inclusion of dispenser cutout, tongue lock, thumb cutout, etc.

When to Choose Reverse Tuck-end Carton:

- When you want to use less material and save cost.

- When you need a sturdy and durable packaging that can carry heavier items.

- If you want to send samples of your products to individuals as gifts.

- If you have a wide range of products in different shapes and sizes.

Conclusion

As mentioned earlier, the major structural difference between straight tuck-end carton vs reverse tuck-end carton is that the former has a simpler and plain tucking system, while the latter has an opposite directional tucking system. This results in many advantages and disadvantages for both packaging styles.

In this post, we’ve highlighted the differences between these two cartons, mentioning which one to choose in specific situations. At GleePackaging, we can help you create the best tuck-end box for your brand and product. Click here to speak with us.