Folding cartons are a common packaging solution used by most businesses and this is because of their wide range functionalities, such as protecting products and promoting business image. Hence, why it’s important to find the right custom folding carton manufacturer that can help enhance your business growth.

There are a couple of factors you need to consider when seeking a quality folding carton packaging solution. In this post, we will share expert tips on how you can order from the right folding cardboard cartons manufacturer for your business.

Let’s ride!

Factors to Consider before Ordering Custom Folding Cartons

Before placing your foldable cardboard boxes order, you need to be sure of certain things, such as the materials the cartons must be made of, the key features the cartons must have, and how urgent the order must be fulfilled. They are further explained below:

What Materials are the Cartons Made of?

There are different types of carton boxes, such as paperboard folding cartons, rigid carton boxes, folding cardboard cartons, etc. Each of them are made of different materials and are suitable for packaging different products. For example, fragile items are best packaged in sturdier materials like rigid carton boxes or paperboard folding cartons, while lightweight items can be stored in foldable cardboard boxes.

The Key Features/Functions of the Carton Box You Need?

Identify the specific features for the carton boxes, such as structural elements, colors, prints, special coatings, etc. For instance, if the items are sensitive to light or water, it’s best you choose cartons that have protective coatings.

The size and shape of the products will also influence the carton features. The carton design can include opening and closing mechanisms that will help the customer to open and close the packaging easily.

In terms of functions, carton boxes are responsible for more than the traditional belief of acting as a container for products. They are versatile and can be used to add a touch of luxury to gifts, products displayed on shelves, branding, and sales demo. You can customize the carton boxes to suit your business goals.

Is it an Urgent Order?

Evaluate the time range for production and delivery. If your order is urgent, note that you might not get full/quality customization as required because of the limited timeframe. On the other hand, you can get the complete and quality customization, but at a higher cost. However, it’s essential to balance urgency with quality to ensure the custom folding carton boxes achieve their purpose.

How to Order from Folding Paper Box Manufacturers

As much as ordering for products looks simple, it’s not the same for folding paper boxes. There are a few steps and knowledgeable decisions you need to make before placing an order. In this folding carton buying guide, we will share with you an expert point of view of how to order from folding carton packaging companies. This will help you make the most informed decision that will propel your business success.

Find the Direct Factory or Manufacturer

A major thumb rule when ordering foldable cardboard boxes is to avoid resellers, especially if you need custom designs or you are buying in bulk. Go directly to the manufacturer or production factory.

As earlier mentioned, product boxes are beyond normal packaging. They create a first impression and impact the lasting impression customers will have about your business. Therefore, you need to find a professional paperboard box manufacturer and communicate all your specifications. You can also discuss your business aims and how the packaging can help achieve them.

Furthermore, it’s extremely important to consider the manufacturer’s experience. A manufacturer with a great reputation and goodwill of success is more likely to meet your specifications and share ideas on how to improve your business image.

Choose Carton Type

There are various types of folding carton packaging you can choose from. Below are the most popular and efficient options:

- Tuck End Boxes: These paperboard folding cartons come with flaps that can be tucked into the front panel to provide tight closure. They are cost-effective, easy to assemble, and offer a professional look. Tuck end box is commonly used for packaging retail products like cosmetics, food items, and pharmaceuticals.

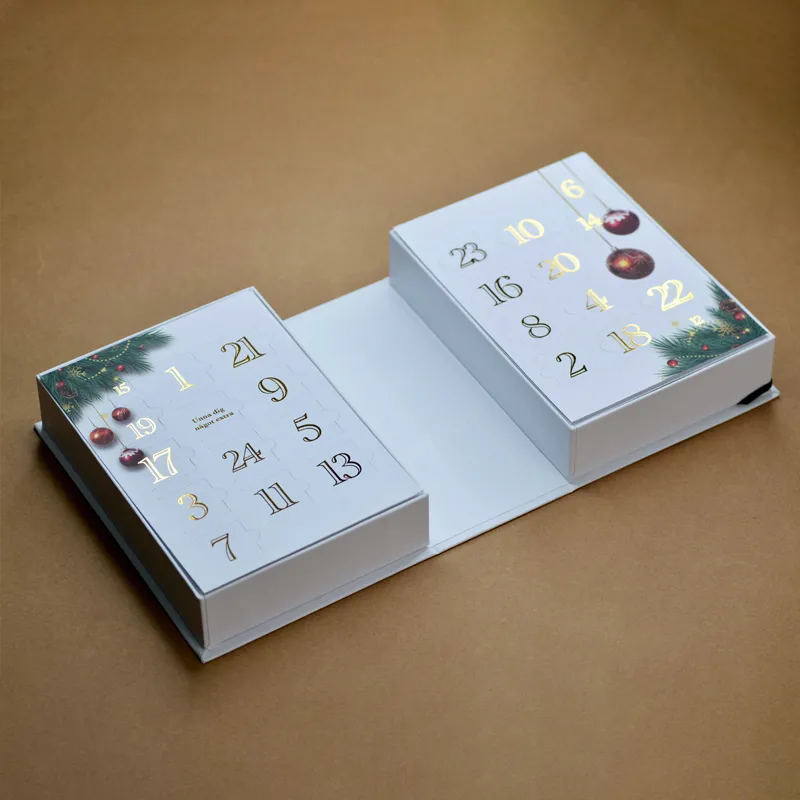

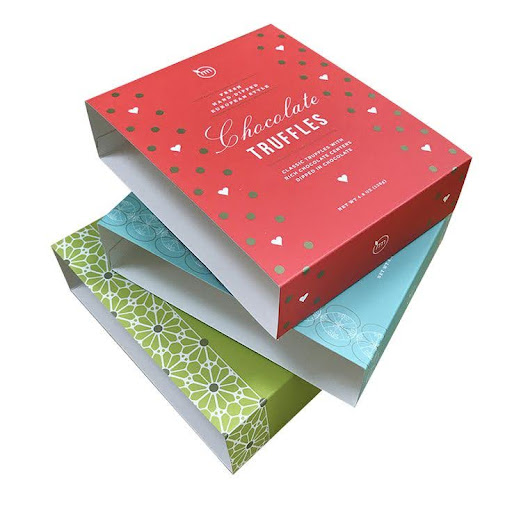

- Trays & Lids: They are also called two-piece boxes. These boxes have a tray-like structure and a separate lid that covers the top, making it easy to access the contents. Tray & lids serve as a secure and protective packaging solution that can be used for luxury items or premium sales presentations.

- Auto-lock Bottom Boxes: Also known as “crash bottom boxes.” They are designed with an automatic locking mechanism at the base to guarantee structural stability. The bottom doesn’t require flaps or tape to lock in place; they are automatically glued together. They are capable of carrying heavy items like electronic devices and items that require extra support.

- Snap Lock Boxes: These packaging solutions have a similar mechanism to magnetic gift boxes. Snap lock boxes feature interlocking flaps that securely snap into place, creating a seamless and visually appealing structure. They offer a sleek appearance, making them suitable for products that require an attractive presentation, such as clothing, promotional materials, and retail items.

- One-piece Tuck-top Boxes: These paperboard boxes packaging looks like mail boxes. They have a single-piece design that comes with a hinged opening and locking flap for secure transportation. One-piece tuck-top boxes are a simple and efficient packaging solution and are most suited for carrying lightweight products like cosmetics.

- Paper Sleeve Packaging: This is an additional packaging that slides over another packaging, typically an undecorated box. It adds an extra layer of protection and aesthetic appeal for plain boxes. Paper sleeve packaging is best used for products that require a premium look, like chocolates, high-end cosmetics, and perfumes.

- Customized Folding Carton Boxes: These are folding cardboard boxes that are tailored to your specific requirements, allowing for unique shapes, sizes, and features. They are designed to meet precise product needs or achieve specific business goals. Custom folding carton boxes are ideal for products with irregular size or shape that require a unique and distinctive packaging solution.

Choose Preferred Folding Carton Material

There are various types of materials used in producing folding cartons. The option to choose depends on factors like the product’s characteristics, environmental considerations, required strength, and desired visual appeal.

Discussed below are the common materials you can choose from:

- Paperboard: Folding paperboard box manufacturing is arguably the most popular and effective type. It’s a thick and rigid paper-based material that comes in various grades, providing different levels of durability and strength. Paperboard is versatile, printable, and customizable to various finishes. It can be used for almost all items, including food, cosmetics, pharmaceuticals, and clothing.

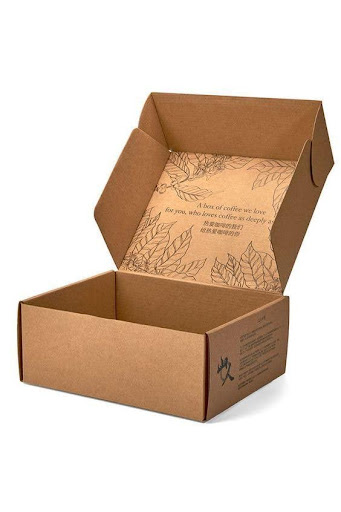

- Kraft Paper: This material is largely known for its natural brown color. It is a durable, coarse paper made from wood pulp. Kraft paper is sustainable and recyclable. It is commonly used for food and retail applications.

- Corrugated Board: This material is made up of a fluted corrugated sheet pasted between two flat linerboards. Corrugated board is strong and durable, making it an excellent option for protecting items during shipping. It is popularly used for shipping boxes, product packaging, and retail displays.

Consider the Folding Carton Shape & Size

When choosing folding cartons, you must consider the shape and size of the products to be packaged. For example, if you sell beauty products like cosmetics, you don’t need big cartons. Rather, order for folding cartons that are compact and visually appealing. However, if you intend to ship multiple products in a one-piece box, the packaging can be considerably wide.

For more accuracy, you can measure the dimension and weight of your products and send it to the paperboard box manufacturer. The folding paperboard box manufacturing should be done to conveniently size your products. Extra space can be added to accommodate inserts like foams that will support the stability of the contents.

Choose Color, Prints, and Overall Design

One of the factors you will consider when selecting among folding carton packaging companies is the best company that can actualize your vision. The manufacturer must be able to produce quality folding cartons in accordance to preferred color, prints, and overall design.

These colors, prints, and overall design are essential for the aesthetics and visual appeal of your packaging. It’s best to choose designs that are in-tune with your business image. Communicate your brand value explicitly with the designs. Let customers see your products and be captivated by the attractiveness of your packaging. For example, if you are choosing a white paperboard box, the print and additional designs should be evidently captured in other colors.

Confirm Finishes

Once the initial print is finished, additional styles and embellishments can be added to elevate the packaging design, giving it a perfect finish.

Some of these include:

- Embossing and Debossing: These two styles add a tactile and visual dimension to folding carton packaging. Embossing raises specific areas of the packaging, creating a textured effect. Debossing, on the other hand, depresses those areas.

These techniques improve the overall aesthetics, giving a luxurious and premium feel to the packaging. Embossing and debossing are very effective for displaying brand identity like increasing the prominence of the business logo.

- Foil Stamping: This process involves applying a thin layer of metallic or colored foil onto specific areas of the folding carton to give extra elegance and luxury to the packaging. Foil stamping is visually striking and shiny, hence why they are used for logo, branding, and intricate details inscription.

- Coating: This is a versatile process that offers both functional and aesthetic purposes. Popular types of coating are glossy and matte. Glossy coating offers a vibrant and reflective look, while matte coating gives a subdued and sophisticated appearance.

Coating does not only improve visual appeal, it also serves as protection against wear and tear, as well as water.

- Lamination: This finishing style has to do with adding a thin layer of plastic film to the folding carton’s surface. Lamination provides many benefits, such as durability, water resistance, and a smooth, polished surface.

Lamination serves as an extra layer of protection, making the folding carton survive handling or environmental factors.

Quantity & Shipping Time

When ordering from folding carton packaging companies, it is crucial to consider their capacity to handle the quantity you need. For example, a small scale company might not be able to handle large quantity orders.

Also, make enquiries about the lead time i.e., the time it will take for the order to be completed and delivered to you. If you are ordering in bulk, be sure that the company can deliver on time, especially if it’s an urgent order. Furthermore, you should ask about the shipping policy, such as costs of transportation, standard shipping times, and other shipping concerns.

Sustainability Concerns

The use of eco-friendly materials and production aligns with the global emphasis on environmental responsibility. Order from a paperboard box manufacturer that uses sustainable materials and manufacturing processes, thereby contributing to the conservation of natural resources and the reduction of deforestation.

Prioritize companies with sustainable packaging services that align with consumer values, as this helps to enhance brand loyalty, save costs, address evolving environmental concerns, and help you stay ahead of packaging regulatory changes in your industry.

Recommendation on Branding Through Printed Carton

You can take advantage of branding through printed cartons and make it a powerful tool for business promotion. Below are 3 cogent tips you should implement to effectively leverage on printed carton packaging:

- Consistent Branding Elements: Ensure that all your printed cartons have the same branding elements, like logos, color schemes, and fonts. Consistency across packaging establishes brand recognition and helps customers identify your products on the shelves effortlessly. Therefore, make strategic use of your branding elements to create a cohesive and reputable business image.

- Storytelling through Design: Use the folding carton packaging as a medium to tell compelling stories about your business or product. Make use of graphics that communicate your brand’s values, mission, and the uniqueness of your product. Doing this does not only capture customers’ attention, it makes them deeply understand and appreciate your brand.

- Quality Printing and Finishing: Invest in sharp and vibrant printing to boost the visual appeal of your packaging and showcase your professionalism. Consider premium finishes like embossing, debossing, foil stamping, coating, and lamination to add a touch of sophistication to your packaging. Quality printing and finishing elevates the perceived value of your product in the eyes of customers.

Key Takeaway

More than ever before, getting efficient packaging solutions has been made easy as there are a ton of folding carton packaging companies on the market to order from. However, it’s important to make certain evaluations before placing an order. In this post, we’ve highlighted the factors to evaluate, with finding a direct factory or manufacturer being the most important.

GleePackaging is a reputable packaging solution provider with a wealth of experience and extensive capability to meet your specifications. Let’s help you get started on leveraging folding cartons to your business success.