Paper is popularly used for packaging because of its ease of folding, recyclability, and environmentally friendly nature. Hence, using paper can be greatly beneficial to you whether you are a brand owner, a retailer, or an individual who wants to gift loved ones.

In this packaging box comprehensive guide, we will discuss the different paper packaging box types, various finishes, printing styles, and advantages. So, whether you are a business person or a consumer, join us to unveil the realities of paper packaging boxes.

Paper Packaging Box Types

Paper is a versatile material that can be used for many packaging purposes, thus its categorization into different types. Explained below are the common types of paper packaging boxes, including how they are designed, their benefits, and applications.

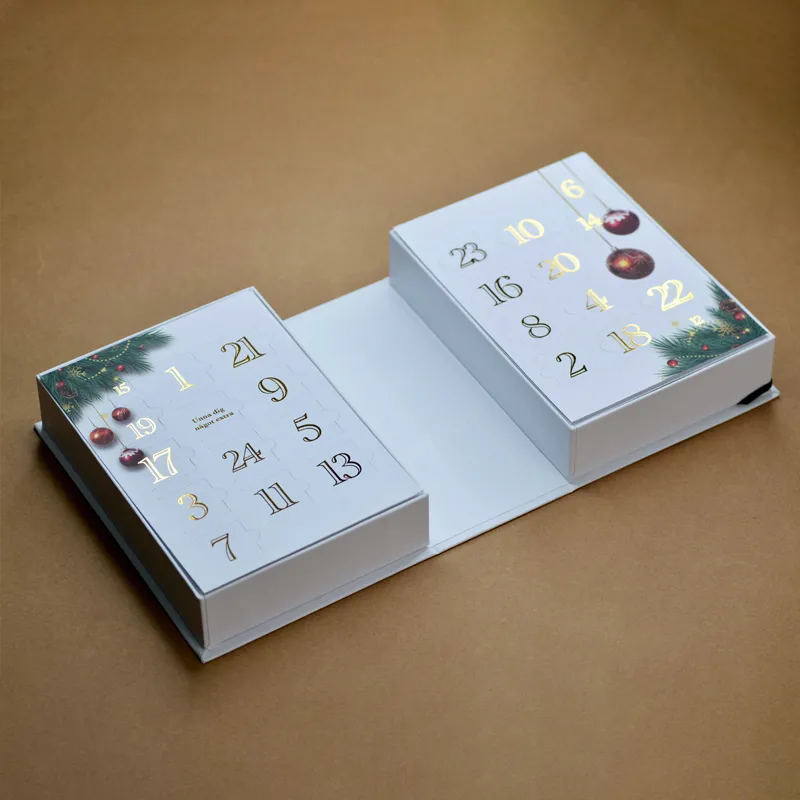

Luxury Gift Box

A luxury gift box is a special type of packaging that is meticulously crafted to convey sophistication and improve the overall gifting experience. Often made from tough paper materials like rigid paperboard, luxury gift boxes exude elegance and quality. They usually have premium finishes, such as embossing, foiling, and intricate detailing.

For these boxes, design is very important, especially since it is skillfully crafted to exude topnotch aesthetics and create a lasting impression on recipients. The boxes don’t just serve as containers or packages, they are typically part of the gift, adding a sense of thoughtfulness and luxury.

Luxury gift boxes are majorly used for packaging high-end products or gifts on special occasions, making the event more memorable.

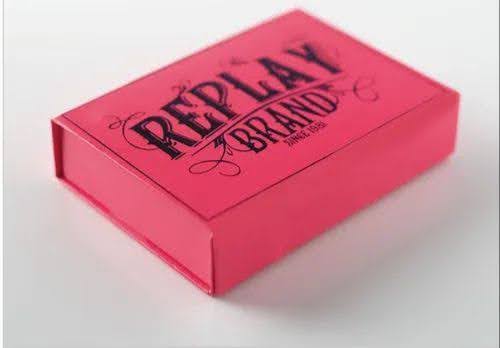

Display Box

Just as the name implies, display boxes are professionally designed to be attractive and compelling. They function as an advertising agent that is used to showcase products’ attractiveness, capture customers’ attention, and drive sales.

These boxes are incorporated in packaging a wide range of items, including jewelry, apparel, cosmetics, etc. Their structural design is focused on balancing durability and visibility. While protecting the items, they also serve as a marketing tool to influence impulse purchase.

Display boxes are popularly used in wholesale and retail settings to exhibit products effectively. Reflective glasses, clear windows, and transparent sections are usually used to allow people preview the products without opening the boxes.

Product Box

Unlike display boxes that serve the dual purpose of protecting the items and acting as a marketing tool, product boxes are tailored specifically to safeguard the items within. They can be customized to different shapes and sizes depending on the items.

The major highlight of a well-crafted product box is its functionality, which guarantees that the items within remain in good shape during storage, transit, and display. They often feature inserts, such as foam or molded pulp inserts to ensure the items are secure regardless of turbulence during transit or frequent customer assessment at the shelf stand.

Additionally, product boxes play a vital role for identifying items on store shelves, allowing customers to easily know your brand and product details, such as the ingredients, usage instructions, and benefits.

Mailer Box

Just as the function of a mail, which is to send information to others, a mailer box is saddled with the primary purpose of conveying products to customers. Made from durable materials like corrugated paperboard, mailer boxes guarantee the safe transport and delivery of goods.

Mailer boxes are designed with a self-locking mechanism, which makes them easy to assemble and convenient. They often incorporate custom printing for brand visibility during shipping.

These boxes can also be crafted to serve the functions of luxury gift boxes. Some are designed with tear strips or adhesive closures, providing recipients with a secure yet accessible unboxing experience.

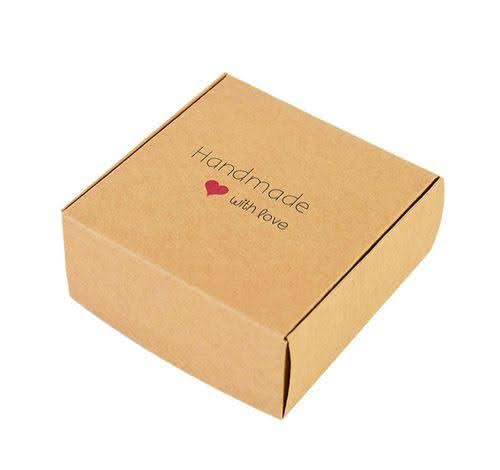

Cardboard Box

Striking a balance between strength and cost-effectiveness, cardboard boxes are versatile and largely used across many industries for packaging products. They can also be customized to different shapes and sizes depending on the specific requirements.

Cardboard boxes are used for literally all aspects of packaging, including storage, shipping, and retail displays. They can be personalized to various styles, such as plain brown boxes for utility or custom-printed for branding purposes.

However, cardboard boxes are not as elegant as luxury boxes nor do they support intricate detailing like display boxes, but they are appreciated for their simplicity, reliability, cost-efficiency, and versatility for packaging a wide range of items.

Paper Packaging Box Finishes

There are many custom packaging boxes services, including finishes that play crucial roles in enhancing the durability, visual appeal, and aesthetics of paper packaging boxes. Whether you want a sleek or tactile experience, choosing the right finish can influence the perceived value of your product.

Below are the 5 major paper packaging box finishes that can elevate customers’ view about your product:

Lamination

This finishing process has to do with applying a thin layer of protective film to the paper packaging box surface. The protective film is made of plastic, making it rigid and capable of serving many purposes like improving the box’s toughness and resistance to moisture, stains, wears, and tears.

In addition, lamination adds a more tactile dimension to the packaging box, making it more visually appealing.

Coating

Coating typically involves applying a liquid substance onto the box’s surface to achieve better visuals or tactile effects. This finishing process adds to the overall aesthetics of the packaging and enhances its resistance against scratches and scuffs.

There are 3 main types of coating: matte, gloss, and satin. Matte coating offers a non-reflective, soft finish, while gloss coating provides a shiny, reflective surface. Satin coating, on the other hand, falls between matte and gloss, with a subtle sheen finish. The type of coating to choose depends on your desired visual and tactile effect, as well as the intended use of the box.

Foil Stamping

Sometimes called “foiling,” this finishing process involves applying a thin layer of metallic or colored foil to certain areas of the box. This results in a shiny, reflective, and attractive design that communicates exclusivity.

Foiling is often used for bolding logos, texts, or intricate details. This in turn adds a touch of luxury and sophistication to the packaging. Embossing or debossing can be added for a more eye-catching effect, hence why it’s commonly used for luxury and high-end products.

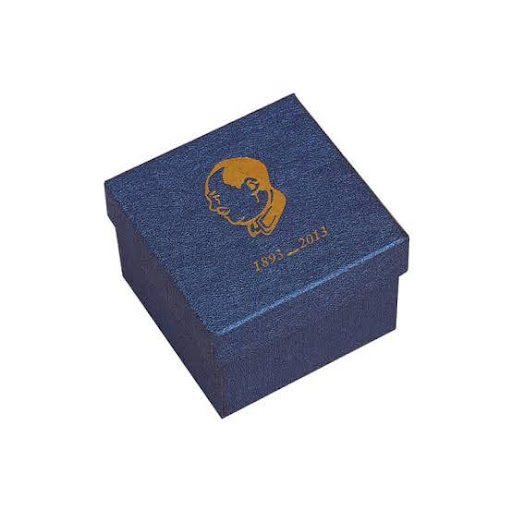

Embossing

This is a finishing process that involves creating a raised pattern on the box’s surface. This is done by pressing the material from the back side, thereby resulting in a three-dimensional effect. It contributes to the texture and tactile effect of the box.

Embossing is usually used on logo, company name, or intricate details, thus giving the paper packaging box a distinctive and quality feel. It exudes a sense of highly-skilled craftsmanship and premium design, making it a commonly used option for luxury boxes.

Debossing

This is the opposite of embossing, as it involves creating an indented design on the box’s surface. Debossing is done by pressing the material from the front side, thereby resulting in a sunken effect. It contributes a sleek touch to the packaging.

Just like embossing, it is usually used to highlight logo, company name, or intricate texts to exude a sense of elegance and luxury.

Paper Packaging Box Printing

There are many printing techniques that can be used for paper packaging boxes. Each of these techniques have their pros and cons, as well as best suited applications.

Below, we will talk about the different types of printing that can be used for paper packaging boxes, tips to follow, and the top 3 most popular colors.

Different Printing Types

Here are the frequently used printing types, including how they work, their pros, and cons:

Offset Printing

This printing method is also known as “lithography.” It’s a widely used technique that involves ink transfer from a plate onto a rubber blanket before it’s applied onto the packaging box surface. Offset printing takes advantage of the non-mixing nature of oil and water, thereby resulting in precise and high-quality reproductions.

Lithography is globally embraced for its many properties, cost-effectiveness for large quantities, and capacity to adequately replicate intricate patterns.

Pros

- Can efficiently produce high-resolution images

- Best option for brochure printing and other extensive applications

- Very cost-effective for large volume production

- Compatible for several paper types and finishes

- Suitable for retail products packaging like apparel, food, and cosmetics

- Color gradients in graphics are smooth and eye-catching

Cons

- Longer setup and turnaround time

- Less cost-effective for small volume production

- Only suitable for flat surfaces

Digital Printing

This is another printing technique used on paper packaging boxes. A few years back, people complained that digital printing doesn’t offer high-quality effects. But with advancement in technology, this printing type has become superb for printing on paper packaging.

Unlike conventional offset printing that involves transferring ink from plates to a rubber blanket, and then to the paper surface, digital printing uses powdered toner for outstanding and ostentatious box designs. It takes the digital image on the paper surface in seconds.

Pros

- Cost-effective for small volume production

- Doesn’t require heavy investment for printing tools and machine

- Quick setup and turnaround time

- Suitable for variable data printing

- Modern digital printing provides high-quality output

Cons

- More costly for large volume production

- Not compatible for all substrates

- Inconsistency in color intensity

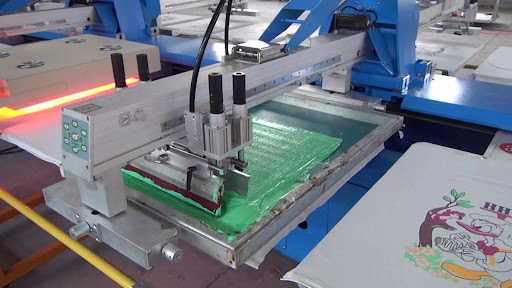

Screen Printing

Also referred to as “silk printing,” this printing technique has been around since the 20th century, yet still one of the best methods over time. It basically involves punching ink through a mesh screen onto the paper surface.

In extension, screen printing entails the design of the specified image and then ink through a screen. Typically, this printing method relies on the efficiency of the screen, and unlike offset printing, the substrate doesn’t have to be flat.

Pros

- Great for pre-made packaging and promotional products

- Printing tools and machine are not expensive

- Suitable for smaller volume production

- Ensure printed designs can withstand wear and tear

- Can work on any surface shape, including flat, curved, etc.

Cons

- Tend to be slower compared to other printing methods

- Setup and operation require expert operation

- Not good for large volume production

- Might not produce ultra-high quality for intricate details

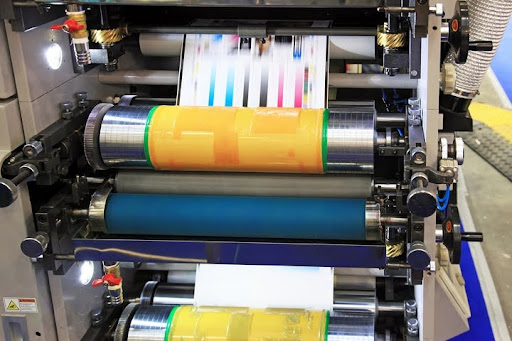

Flexographic Printing

This technique involves a flexible relief plate that’s often made of rubber or photopolymer, mounted on a rotating cylinder. The inked plate transfers the image or text onto the paper packaging box’s surface. It offers high-quality HD and full colors printing, catering to all your audience needs.

Flexographic printing is a great option for high volume printing needs and is typically used for packaging applications like labels, gift wraps, and other custom paper packaging boxes that require a continuous printing pattern.

Pros

- Less costly than other printing methods

- Uses water-based, solvent-based, and UV-curable ink toners

- High speed production

- Can print on uneven surfaces

Cons

- The setup process generates large waste

- Low print quality for fine details and intricate designs

- Changing colors requires changing the printing plates

Tips to Follow

Creating great paper packaging boxes is more than a mere industrial process. It is an extensive form of art that demands top-class creativity, precision, and technicality. The packaging industry is full of opportunities for ideas and craftsmanship that can set a brand apart from others.

If you want to customize your paper packaging boxes in the best way to promote your business, attract customers, and drive up sales, explore these tips:

- Understand Your Product: Firstly, the type of packaging and printing you choose is dependent on the nature of your product. For example, if you sell luxury products like diamond jewelry, your packaging box must be extremely eye-catching and able to convince shoppers to buy. Also, it must exude a sense of exclusivity and give customers a memorable unboxing experience.

Another angle to this is the fragility of the product. It’s recommended that you choose a sturdy packaging that can withstand turbulence, wear, and tear.

- Prioritize High-Resolution Prints: Make sure the printed images and texts are in high resolution in order to get crisp and clear prints. This will allow consumers to have easy visibility about the information on the packaging. Calibrate your color profiles for accurate color reproduction. Having uniform color across all printed designs is important for maintaining your brand identity.

- Pay Attention to Intricate Details: Every pattern and design in a paper packaging tells a story. Every fine detail and intricate design on the packaging can be likened to sculpting a piece of art. Thus, it’s crucial to skillfully print the images and texts on the box. Furthermore, it’s best to use inks that can sustain frequent touch and movement.

- Typography Considerations: Be 100% invested in the grammar, font sizes, and styles of the texts printed on the packaging. Ensure the texts are easy to read and don’t lose clarity, particularly when scaled down because of limited space. Use fonts that match the box’s design theme and comply with your brand identity. A thorough assessment of the typography helps avoid mistakes that could result in costly reprinting.

- Evaluate the Production Volume and Costs: Depending on the quantity of boxes to be printed on, there is a variation of printing techniques to choose from. For instance, offset printing is best suited for large volume printing, resulting in total cost reduction in the long run. Digital printing, on the other hand, is best suited for smaller volume printing and the customization is pretty cheap.

- Sustainability Considerations: In compliance with the rising trend about environmental consciousness, paper packaging boxes should be made with eco-friendly materials that showcases your brand’s dedication to sustainability without compromising on quality. Ensure you use inks that are safe for the environment. Also, the printing should be professionally done to avoid peeling off.

Top 3 Most Popular Colors

The ideal color of paper packaging box can be based on industry trends, brand identity, and design preferences. But overall, the 3 most popular colors that stand out for their impact and visibility are:

- Cyan, Magenta, Yellow, and Black (CMYK): This is a model that consists of a blend of cyan, magenta, yellow, and black in varying intensities. CMYK is great for vibrant, high-quality prints with a full range of hues, which makes it ideal for several designs and product types. The color combination effectively reproduces complex images, providing realistic and detailed prints.

- Pantone Spot Colors: These are standardized inks that are pre-mixed for precise and consistent color reproduction. Pantone spot colors are valued for their solid and vibrant appearance, which makes them commonly used for logos and brand-specific elements. Many brands use this color mix to maintain a specific accurate identity.

- Black: This is a vintage and timeless color that reflects elegance and sophistication. Black is usually used for luxury packaging as an indication of exclusivity. Furthermore, black offers excellent contrast, making it great for highlighting logos, texts, and other design elements. It also helps with readability and can be combined with other colors to create a visually striking packaging.

Why does it Matter: A Great Paper Packaging Box

Over the years of observing human psychology, it’s been discovered that packaging design influences the purchasing decision of many consumers. Hence, why there is a popular quote that says: “people buy based on their emotions and justify their decisions logically.”

This proves that a great paper packaging box impacts customers’ perception about your product and brand, which affects your sales. Below, we will highlight how great packaging boxes help your business grow.

Promotion of Brand Awareness

One of the primary functions of packaging is to send desired messages to your target audience, thereby increasing your brand awareness. In fact, with a great paper packaging box, you can increase the product’s value by making customers mesmerized with the outer appearance.

Generally, with a well-designed packaging, you can evoke consumers’ emotions and establish your brand into their subconsciousness. When this happens, they begin to talk about you to other people. That way, you’ve gotten people to do advertisements on your behalf. Word-of-mouth recommendations, especially from family and friends, have proven to be a more effective marketing tool.

Product Protection

Most times, products returned by customers can be traced to damage, which could have happened during shipping. Meanwhile, product returns can cost you in a big way and eat largely into your profit. A salient way to curb this is to have a sturdy packaging box that can withstand turbulence during transportation. Attractive designs won’t mean anything if customers get damaged products.

Consider the shape, size, and weight of the product. This will help you choose the most appropriate box design for packaging. You can incorporate inserts and fillers to make the product secure during transit.

Memorable Unboxing Experience

Customers’ unboxing experience matters a lot, especially in this age where people want to share their unboxing expression with loved ones or post on the internet. Typically, many customers go back to a brand when their ordered items come in a premium package, as it makes them feel special. Doing this is one of the ways to put your brand in the subconsciousness of customers.

Furthermore, you can leverage on customers’ unboxing experiences to build your profile by adding them to the remarks gotten from consumers. You can post the videos on your business website and social media. The visual expression can convince more people to buy from you.

Use of Eco-Friendly Materials

In recent times, people have become aware of the environmental issues caused by regular packaging. This has resulted in customers choosing products that are packaged in eco-friendly materials over products that are packaged in regular materials. Helping to keep the environment safe can boost your business reputation and make consumers love your brand more.

Beyond that, you will get greater joy doing something good for the planet Earth. The sense of pride and confidence to defend your brand and products will be priceless.

Key Takeaway

Paper packaging boxes are one of the most preferred packaging used all over the world because of their many properties. They are cheap to acquire and can be easily customized to your desired taste, making you capable of catering to your audience needs.

In this post, we’ve highlighted the various paper packaging box types, different types of finishes, printing techniques, and their benefits to your business. Having professional assistance can be really helpful in helping you make the right decision on how your packaging should be designed. Contact GleePackaging today to create the best paper packaging box with the ideal size, shape, weight, and custom designs.