Packaging odd-shaped items can be a daunting task compared to items that have standard shapes and sizes. You have to think outside the box because irregularly shaped products cannot fit into regular packaging.

The Unique Challenges of Odd-Shaped Goods

Defining “Odd-Shaped” in the Packaging World

Some items have irregular contours, protrusions, or fragile ends. You often see them in sculptures, machinery parts, and uniquely designed furniture. This means that they cannot be packaged in the common rectangular or square boxes. Instead, they need customized boxes or containers.

This calls for knowing the difference between non-standard size and non-standard shape. They have different effects when considering irregularly shaped items.

- Non-standard Size: Refers to products that are unusually large, long, or small. For instance, an oversized display panel or a very small precision tool.

- Non-standard Shape: Refers to products whose form doesn’t sit neatly in a uniform container. For example, a statue with an extended arm or a lamp with a wide base & narrow neck.

Common Examples of Irregular-Shaped Items

Weird-shaped items appear across almost every industry. For easier relatability, we categorize them into primary and secondary groups.

- Primary/Retail Examples: These are commonly handled in e-commerce, retail distribution, and consumer packaging. They include cosmetics containers, oddly shaped glassware, molded plastic toys, rigid blister packs, and consumer electronics with non-rectangular screens.

- Secondary/Industrial Examples: These are typically larger, heavier, or mechanically complex items found in manufacturing, automotive, and industrial logistics. They include assembled machinery, auto parts, medical equipment, furniture, and long items with non-uniform thickness.

High-Risk Factors in the Shipping Process

Odd-shaped boxes introduce high risks during shipping. Their structure affects everything from cost to safety.

Here are the main challenges you should keep in mind:

- Dimensional Weight (DIM): Shipping companies don’t charge only the actual weight of the packaging, they also evaluate the dimensional weight, which measures the amount of space the packaging occupies. This means that even if the product itself is light, but the size is wide, the shipment is categorized in the higher DIM bracket.

- Vulnerability to Damage: The more protrusions an item has, the more vulnerable it is. Irregularly shaped goods are known to have uneven surfaces that create pressure points. They also have an unbalanced weight distribution. These can lead to breakage, surface defects, or internal component stress if not packed well.

- Movement within the Box: An item with uneven sides or weight distribution doesn’t sit firmly in a rectangular box. Any void space can cause shifting, tilting, or rotation during transit. All these motions increase the chance of damage.

Warehousing and Storage Considerations

Irregular packaging, like odd-shaped cardboard boxes can easily disrupt how a warehouse uses its space.

- Space Utilization: Most storage systems are designed around consistent, predictable dimensions, so anything outside that norm tends to interrupt the layout.

- Racking Systems: Some items may not sit securely on standard racks, requiring added supports or strapping to keep them stable.

- Inventory Management Efficiency: They slow down inventory work. Because the surfaces are uneven, placing barcodes or labels isn’t always straightforward, and staff may need extra time to scan, count, or position them correctly.

Best Practices for Secure Shipping and Protection

Protecting and shipping odd-shaped items is entirely different from how products with standard structures are packaged.

Below are the essential facts you need to know for secure shipping and protection of odd-shaped items.

Selecting Packaging Layers: Primary vs. Secondary Considerations

Before an odd-shaped product goes anywhere, it needs the right combination of primary and secondary packaging.

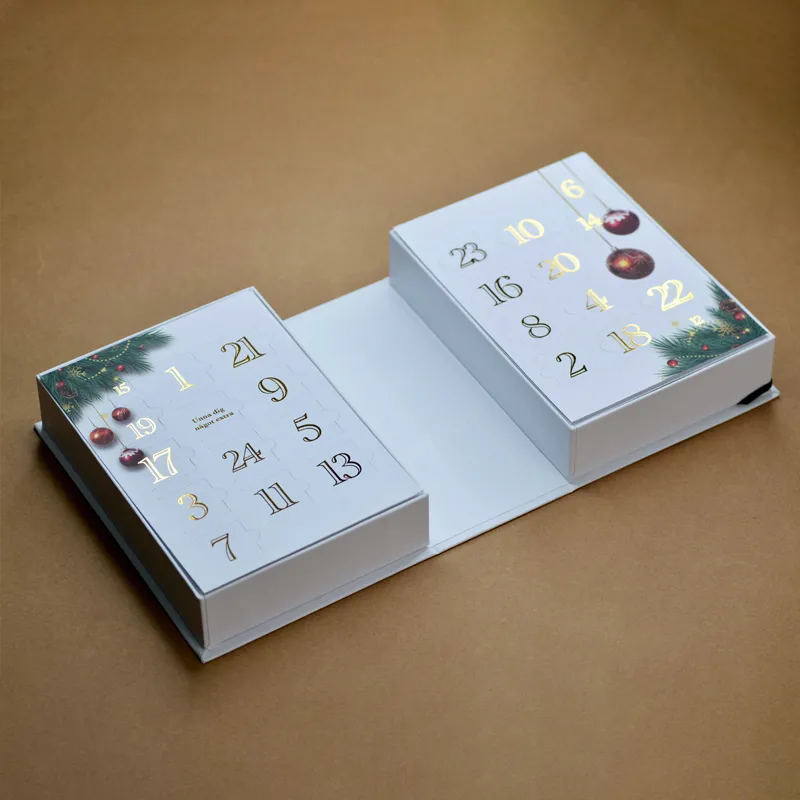

- Primary Packaging Focus: This is the first layer that touches the product. It must match the item as closely as possible to maintain stability and presentation. Custom inserts can be added to cradle every curve or protrusion, as well as using clamshell packaging that’s molded according to the product’s profile.

- Secondary Packaging Focus: This is the outer packaging, i.e., the shipping box, mailer, or crate that’s responsible for surviving outside conditions. Choosing the right container to house the primary package contributes to the product protection and stacking efficiency.

Other considerations include:

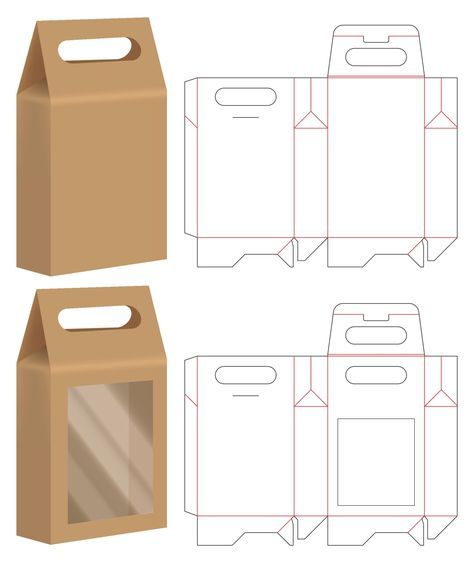

- Using custom die-cut and corrugated solutions (Nylon/E-flute) for secondary protection.

- Using double-wall boxes for moderately heavy or awkward items.

- Using triple-wall boxes for large machinery parts, dense materials, or products that could otherwise burst through standard packaging.

- Using crates, skids, or pallets for items that cannot be boxed due to their size.

Internal Cushioning and Void Fill Techniques

After the packaging is selected, the next step is managing movement and impact from all angles.

- Blocking and Bracing: This involves using foams or engineered inserts to stop the product from possibly moving. Blocking and bracing is very useful for machinery parts, electronics, and furniture components.

- Contour Filling: When you can’t brace every contour with rigid supports, the next best option is to fill the negative space using molded pulp or air pillows. This will eliminate empty pockets where the product could shift or rotate to.

- Suspension Packaging: You need suspension systems like stretched film or mesh to prevent the product from getting damaged. Even if the outer packaging gets hit by a hard object, the product remains untouched. It’s essential for fragile items.

Labelling and Carrier Communication

Due to the delicate nature of most odd-shaped packaging, it’s important that they are properly labelled to prevent mishandling. The most necessary labels are:

- This Side Up: means the packaging must be positioned upward.

- Fragile: for packaging with breakable components or protrusions.

- Non-stackable: means do not place other items on them.

- Heavy Item—Team Lift: means one person shouldn’t carry it alone; there should be support from every side.

Best practices for applying freight classification and dimensional data accurately include:

- Recording the actual weight and dimensional weight for carrier assessment.

- Applying the correct freight class, whether this side up, fragile, non-stackable, etc.

- Communicating any special instructions in advance.

Optimizing Warehouse Storage and Inventory Management

Storing a weird shaped box isn’t just about finding a space to put it. There needs to be a system that keeps the box stable and easy to access.

Effective Palletizing for Irregular Loads

The goal is to create a solid, stable load that won’t shift or collapse during handling.

- Start with the strongest, flattest components at the bottom. Position the packaging so their weight is evenly distributed, and avoid overheating.

- Use industrial shrink wrap and securing materials to keep everything in place.

- Create flat, safe layers with dunnage (e.g., corner boards and honeycomb pads). It makes the entire pallet load easier to wrap, store, and stack.

Utilizing Non-Standard Storage Solutions

Even the well-organized warehouses struggle when odd-shaped gift boxes don’t fit into their racks. That’s why specialized solutions are important.

- Implement gravity flow racks for faster access to small, irregularly-shaped products that are often needed.

- Use cantilever racking for long, slender, or unusually shaped goods (like pipes, tubes, or frames).

- When dealing with seasonal surges or bulk shipments, it’s advisable to set a flexible “Irregular Overflow” zone to keep the warehouse organized.

Streamlining Warehouse Movement and Picking

To further optimize the warehouse activities, you have to make concrete plans on how to avoid slowdowns or work hazards.

- Design efficient pick paths with the size, weight, and shape of items in mind. For example, larger items should be stored closer to the main aisle, while high-frequency items should be placed in easily accessible zones to reduce travel distance.

- Initiate specialized handling equipment, like forklift attachments, dollies, and rolling cradles to help workers and reduce the likelihood of product damage.

Partnering for Custom Packaging Solutions

Sometimes, the only way to properly protect a weird-shaped box is to stop forcing it into standard packaging, but instead build something tailored to its exact needs. For this, you need a professional printed box packaging manufacturer—offering the technical expertise, materials knowledge, and design capabilities to manufacture the right packaging solutions.

When Off-the-Shelf Fails

Standard packaging works only up to a point. When frequent product damage or high DIM fees start increasing total costs, custom packaging becomes the smarter choice. A packaging manufacturer will evaluate your product’s shape, the fragility, and shipping conditions to design protective, tailored solutions.

Finding the Right Manufacturing Partner

Strictly screen the manufacturers and choose one that has experience with your industry and proven expertise with your choice of material (whether foam, corrugated, plastics, etc.). Request for material certifications, prototyping capabilities, and lead-time estimates.

This ensures that the manufacturer can deliver consistent quality within a definite time and manufacture odd-shaped boxes that comply with regulatory requirements.

The Customization Workflow

Customization begins with defining product specifics like weight, fragility, and handling environments. From there, you will provide/co-create accurate 3D CAD files or product samples so the packaging manufacturer can design and test the prospective solutions.

This structured workflow eliminates guesswork, reduces errors, and creates packaging that fits perfectly and performs reliably.

Essential Packaging Materials and Equipment

The best packaging strategy depends on having the right materials and tools. This section highlights the key materials and technologies that support optimal packaging manufacturing of odd-shaped boxes.

Customization and Design Services

Working with a packaging manufacturer adds professional insight that improves protection, reduces material waste, and lowers long-term costs. It’s always advisable to include custom foam inserts and die-cut corrugated designs. Although the addition may increase costs, it’s beneficial in the long run—minimizes damage rates and increases customers’ satisfaction.

Sealing and Securing

Choosing the right sealing method is crucial. There’s a contention of which is better between industrial-grade filament tape and standard packing tape. The former is better because it offers higher strength and tear resistance, making it a better option for heavy or irregularly-shaped containers. After taping, you can use polypropylene or steel strapping for extra stability. This will prevent movement during transport.

Investing in the Right Equipment

Get top-grade equipment that offer consistent protection, faster workflows, and lower packaging costs. An example is foam-in-place machines, which are excellent for high-volume operations or uniquely shaped items. They create custom-fit cushioning on demand. Other top equipment are stretch-wrap machines and turntables to improve pallet stability, reduce film waste, and speed up loading.

Conclusion: Making the Irregular Routine

Odd-shaped packaging becomes a success when the right materials, design strategies, and equipment are in place. From custom inserts to secure sealing methods and efficient machinery, each choice strengthens protection and workflow reliability.

With thoughtful planning and partnering with a professional packaging manufacturer, even the weirdest-shaped products would have their customized boxes and containers. This will reduce damage during transit or handling in the warehouse.