If you love to shake presents before opening them or you care about the safety and presentation of items, you would be very concerned about the protective measures in the packaging box.

If the box is bigger and inserts are not inside to hold the items in place, they will likely jiggle. This can result in damage or a distorted arrangement of the items. To prevent any disruption, it’s recommended that you use the right custom inserts.

In this post, we will explore everything you need to know about custom box packaging inserts, including why they matter, the various types, how to choose the right insert, the benefits, drawbacks, and how to design effective box inserts.

What are Packaging Inserts and Why Do They Matter?

Definition and Function

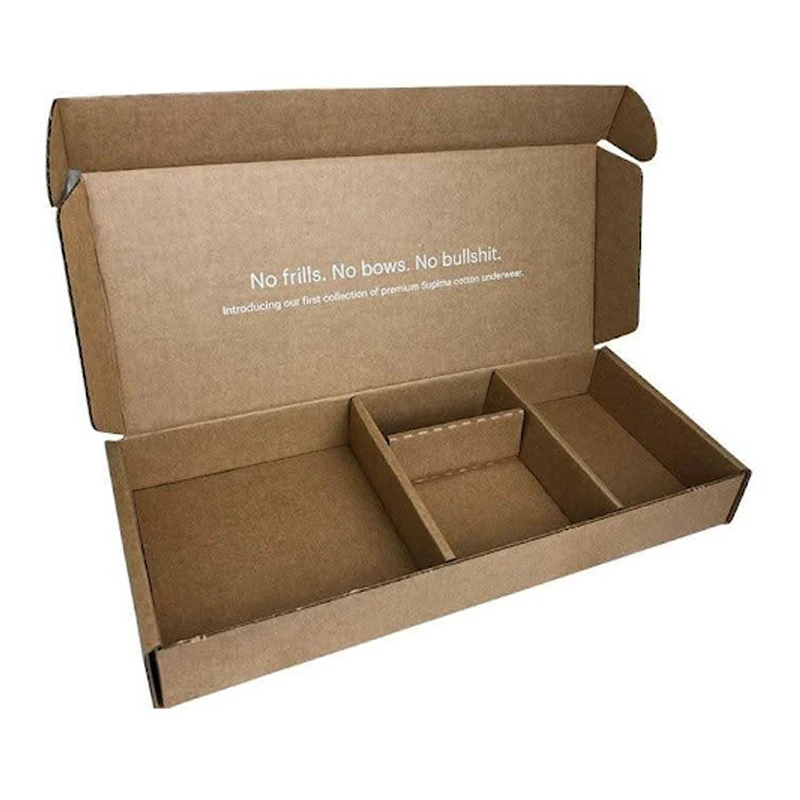

Packaging inserts are specialized interior components designed to fit inside packaging boxes to provide firm structure, protection, and organization. These box inserts are available in several forms, such as cardboard box divider inserts (to separate multiple items), trays (to protect individual products), and fillers (to absorb shock during transit).

The primary function of packaging inserts centers on product safety, ensuring items are secure and safe throughout handling, shipping, and storage. They prevent the items from rubbing against each other, up-and-down motion, and side-by-side movement.

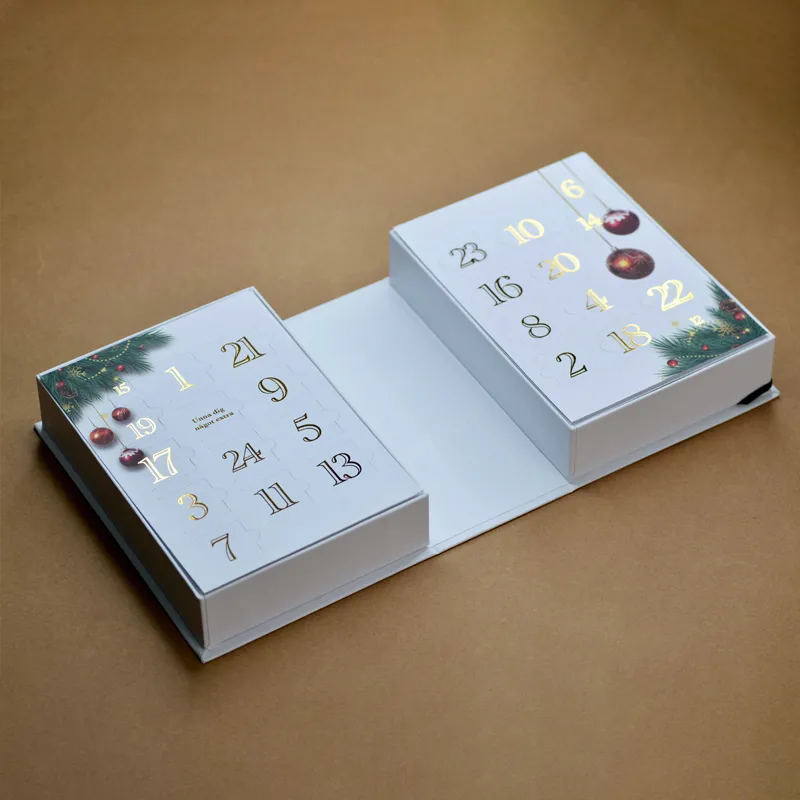

Well-designed inserts enhance unboxing moments, communicate quality, and professional presentation that influences customers’ perception and loyalty.

Industries that Benefit from Packaging Inserts

These are some of the industries that include inserts in their packaging boxes:

- Cosmetics: Rely heavily on custom inserts to package makeup palettes, skincare sets, body sprays, and perfumes, while maintaining product integrity.

- Electronics: Use precision-fitted inserts to protect sensitive components like mobile phones, computer accessories, and headphones from impact damage.

- Food and Beverage: Utilize custom inserts for wine collections, fruit gift sets, and artisanal product assortments.

- Subscription Boxes: Include inserts in creating curated experiences that build anticipation and brand recognition.

Types of Custom Box Packaging Inserts

Here are the common and effective custom inserts you can use for your packaging boxes:

- Foam Inserts

Foam box inserts represent the premium choice for protecting fragile, luxury, or high-value products. They are often attached to a custom mailer box, with high-end appearance and excellent protection against impact, vibration, and compression forces. However, they are quite expensive and less eco-friendly unless recycled foam is used.

- Cardboard Inserts

Cardboard inserts offer versatile, recyclable, affordable solutions ideal for lightweight products or multiple packaging situations like books, documents, and small accessories. But cardboard box inserts offer limited cushioning and a less premium aesthetic that may not align with luxury brands.

- Molded Pulp Inserts

Molded pulp inserts cater specifically to eco-conscious brands who prioritize sustainability without affecting product protection. These inserts are made from recycled paper materials, resulting in biodegradable, sustainable packaging that offer good protection. However, they are not usually dimensionally fit for packaging and they have an industrial appearance that may not suit premium brand packaging.

- Plastic Inserts (Thermoformed Trays)

Thermoformed plastic inserts are best for high-volume production, such as cosmetics, electronics, and consumer goods that require clean product display and consistent quality. They are custom-molded for perfect fit and cost-effective when made in large quantities. But the environmental concerns regarding plastic waste disposal is a problem for sustainability-focused brands.

- Paperboard Dividers

Paperboard dividers serve as an economical solution for separating small or lightweight items within a packaging corrugated box. They are lightweight and offer extensive customization options for printing brand or product information. But these inserts are not durable, thus not suitable for heavy items.

- Fabric or Velvet Inserts

Fabric and velvet inserts are best for packaging that contains jewelry, watches, and luxury goods. They are usually attached to a rigid box packaging, ensuring durability, premium feel, and memorable unboxing experience. However, they are expensive and used for only high-end items.

Choosing the Right Insert for Your Packaging Needs

Selecting the right insert for your packaging needs requires careful analysis of multiple factors that directly impact the product protection, your brand perception, and business profitability. These factors are:

- Consider Product Type and Fragility

The product type and fragility is the basic foundation for insert inclusion in packaging boxes. Ensure you choose an insert that complements the product. For example, if it’s a fragile item like glassware, ceramics, or electronics, you can use foam shipping inserts to absorb possible shock and protect the item. On the other hand, if it’s a tougher item like books or clothing, you can use plastic or cardboard inserts.

- Think about Brand Positioning

The insert should align with your overall branding. Luxury brands require premium materials like fabric or velvet. Eco-friendly brands should prioritize sustainable materials like recyclable cardboard or molded pulp inserts. Brands that focus on minimalist styles should use simple inserts like paperboard dividers.

- Evaluate Budget and Volume

Your budget will influence the choice of material to use. For example, if you have a limited budget, choose affordable inserts like cardboard and paperboard dividers. But if you have a robust budget, you can select premium inserts like foam, fabric, or velvet. Also, consider their cost-efficiency for small vs large production runs.

- Sustainability Goals

According to Business Waste Management, 40% of plastic waste is from packaging and in the EU, paper and cardboard were the main packaging waste material from 2011 to 2022. In light of these saddening statistics, choose recyclable and biodegradable options, especially for brands that advocate environmental sustainability.

Benefits of Using Custom Packaging Inserts

- Enhanced Product Protection: Custom packaging inserts play a huge part in preventing damage during shipping, handling, and storage of products. They eliminate product movement within the shipping box, preventing scratches, dents, and breakage that may result in customer dissatisfaction.

- Improved Unboxing Experience: Inserts ensure products are organized and look presentable for visual appeal and customers’ delight. This creates a positive first impression and unpaid publicity when customers share their unboxing experience on social media.

- Better Branding Opportunities: Apart from customizing the product and packaging box to promote your brand, inserts can also be designed to reinforce your brand identity. They can be configured to have your brand’s colors, shape, and printing elements.

- Efficient Space Management: Custom inserts help to optimize the packaging box layout to reduce waste and shipping costs. This is most especially helpful when you have many items. You can group them into different sections, separating them with the inserts.

Drawbacks and Considerations

- Added Cost: All businesses, particularly small-scale businesses, dread the thought of incurring more expenses. Well-designed custom inserts can be quite expensive, adding to the overall cost of the product packaging.

- Storage and Shipping Space: Some insert materials can be bulky, resulting in the manufacturing of bigger packaging boxes so that they will fit in. This significantly impacts the required storage and shipping space.

- Design Complexity: Custom packaging inserts require precise designing to ensure proper fit and function. Improper designs and fittings will create customer frustration and potentially damage the product.

How to Design Effective Box Inserts

Designing effective box inserts demands for professional packaging manufacturing expertise and attention to detail. The design process involves 3 critical stages that will determine how the inserts will impact the overall product packaging.

Stage 1: Get Accurate Product Dimensions

Start by measuring the product to know its dimensions, as this will influence how the insert will look like. Essential measurements include the length, width, height, and fragile attachment points that must be considered. While measuring, account for space tolerances and temperature-related expansion or contraction during transit.

NOTE: A minor measurement error can result in loose fits that will cause the product to move or be too tight, which can result in damage.

Stage 2: Work with Packaging Designers/Packaging Manufacturers

Partner with an experienced printed box packaging manufacturer to get quality results. Communicate your ideas with the manufacturer and monitor closely as they bring your vision to life.

Professional packaging manufacturers use CAD software to create precise 3D models, which allows you to see how the finished result will be before going forward. When satisfied with the 3D modelling, they produce prototypes of the inserts for testing to ensure proper fit in the packaging box.

NOTE: First batch of inserts shouldn’t be produced in large quantities even though you’re satisfied with how it looks.

Stage 3: Test for Real-World Performance

The first batch of inserts should be tested in the real world. Stack them in your product packaging and keep some in your warehouse while others are shipped to customers. Go to the warehouse daily to check if there are changes with the structural integrity of the inserts or products. Also, pay attention to customers’ feedback. You can even directly ask your loyal customers what they think about the inserts.

NOTE: The feedback will determine if more batches should be produced or the insert style should be changed.

Conclusion

Custom inserts play a huge role in maintaining the safety of your products and ensures that your brand presentation isn’t disrupted throughout the movement cycle of the packaging. There are various types of inserts (such as foam box inserts, cardboard inserts, molded pulp inserts, plastic inserts, paperboard dividers, and fabric/velvet.

When you choose the right one for your brand, you can rest assured that your products will be protected, packaging space will be managed efficiently, customers will enjoy their unboxing experience more, and your brand will be further promoted.