Chipboard and cardboard are common packaging box materials. Both materials can be customized with various prints and design elements to increase your brand visibility and protect products.

There is often a chipboard vs cardboard comparison because of their unique qualities, which makes one more suitable than the other in certain applications. In this post, we will analyze the differences between both materials, highlighting their pros, cons, and common applications.

What is a Chipboard?

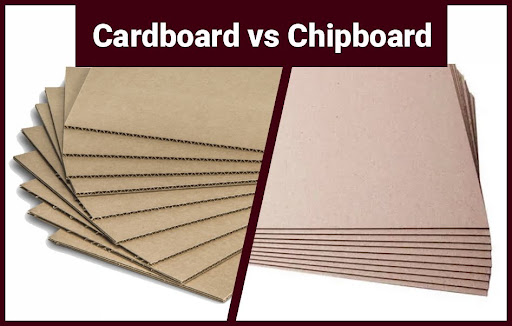

Chipboard is a tough paperboard made from a slurry of hot water and recycled paper that’s compressed to be very thick. This configuration process makes the material have a fine, clean finish. Chipboard is generally used for products and rigid gift boxes because of its smooth surface and pressed edges.

Pros

- Chipboard is made from recycled paper, making it a sustainable option for brands that want to minimize their environmental footprint.

- It offers a perfect canvas for printing, with a plain surface that improves the luster and vibrancy of your designs.

- Chipboard is lightweight, which is beneficial for applications where weight minimization is crucial.

Cons

- Compared to cardboard, chipboard is less durable and can’t be completely trusted to withstand moisture and rough handling.

- Because of its lightweight, it’s unsuitable for heavy-duty applications.

Common Applications of Chipboard

- Food and Beverage Industry: Chipboard stands as a cornerstone in the food and beverage industry for packaging. Thanks to its unique features, it is easily customizable to entice consumers, as well as guarantee the product and environment preservation.

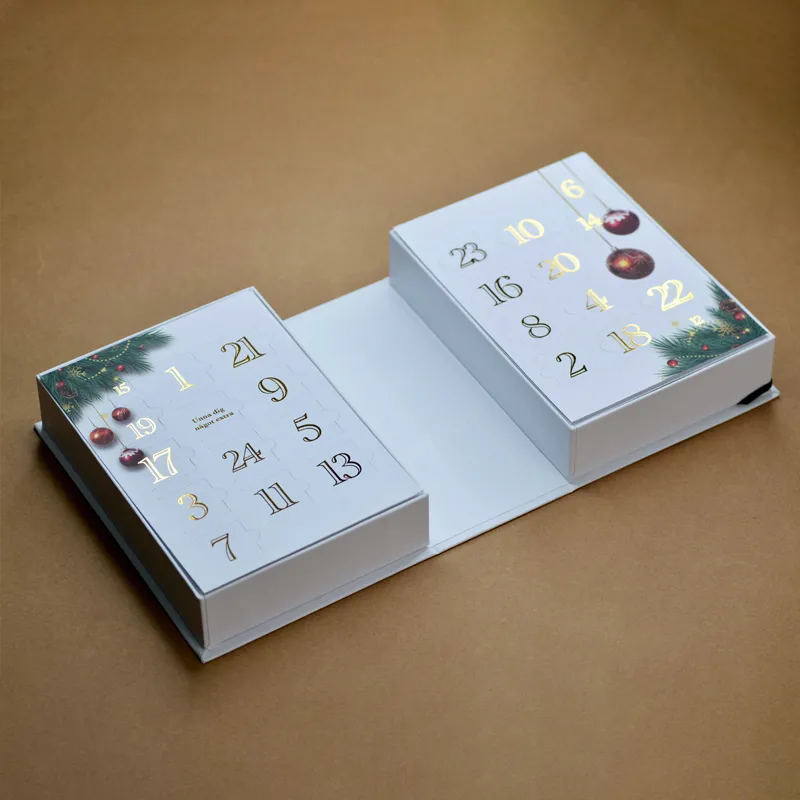

- Cosmetics and Beauty Industry: The glamorous world of cosmetics and beauty packaging finds a partner in chipboard because of its plain surface for sophisticated printing and design. Its fine customizable nature allows for endless personalization, modifying ordinary boxes into images that capture customers’ attention and enhance your brand allure.

- Flower and Decoration Industry: Flower and decoration boxes are increasingly popular in the market. They are often packaged in chipboard to meet different floral designs and offer a sense of exclusivity. The material allows the box to be patterned and folded to the shape of the flower, thereby enhancing the overall aesthetics.

What is a Cardboard?

Cardboard has a fluting layer of card sandwiched between a top and bottom layer of linerboard. The fluting makes the cardboard able to carry heavy weight, with cushioning to protect the product. Even though it is stronger than a chipboard, it can be folded and configured into different sizes and shapes easily.

Pros

- Cardboard has better strength and can withstand various rough handling and shipping turbulence, guaranteeing the safety of your products.

- It can be easily cut, folded, and configured into any shape to accommodate your product.

- Cardboard is more affordable. It’s widely available, making it a pocket-friendly option, especially for small scale businesses.

Cons

- While cardboard can be recycled, the process is resource-intensive, making it less sustainable.

- Cardboard enhances deforestation and greenhouse gas emissions.

Common Applications of Cardboard

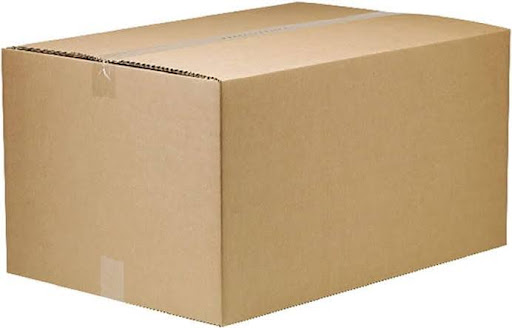

- Electronics Industry: Cardboard, with its strength and durability, carries heavy and delicate electronic parts. It also acts as a reliable insulator, safeguarding electronic devices from static electricity during shipping.

- Small-scale Furniture and Appliances Industry: During transit, cardboard’s rigidity ensures the safety of furniture and appliances, as well as protects them from scratches and damages. Regardless of the furniture’s uneven shape, the cardboard packaging can be configured in square or rectangular shape with inserts inside to stabilize the content. This allows for easy mobility.

- E-commerce and Shipping Industry: Thanks to cardboard’s strength and capability to withstand pressure during transit, e-commerce and shipping companies often use it for packaging. In addition, it’s economical and easily obtained, making it a budget-friendly option. This enables them to charge lesser fees for product deliveries.

Which is Cheaper?

Cardboard is cheaper. Its economical nature stems from its widespread availability, making it a budget-friendly option for businesses with financial constraints.

Which is Stronger?

Cardboard is a thick paper pulp creation, with strength to withstand pressure. Its sturdiness makes it ideal for packaging fragile or delicate items, such as glassware, ceramics, porcelain, artwork, and electronics.

Main Differences between Chipboard and Cardboard

Chipboard is often seen as the newcomer, but its advantages have made it gain momentum in the packaging industry. This is not to take away the excellence of cardboard over the years.

Now, let’s have a comparison of chipboard vs cardboard, considering crucial factors that will influence your choice.

Strength and Durability

- Chipboard, which is made from compressed recycled paper, is denser and notably more robust. To some extent, it excels in strength and durability, protecting items from damage.

- Cardboard, on the other hand, is made from a thick paper pulp. It’s tougher than a chipboard, making it capable of withstanding more pressure. Generally, cardboard can be more trusted to protect your products.

Ease of Customization

- While both materials are easy to customize, the chipboard stands taller. It supports versatile customization, allowing you to cater to diverse packaging needs. Furthermore, it seamlessly embraces intricate designs and cuts, making it suitable for specialized packaging solutions.

- In terms of customization, cardboard shouldn’t be put aside. It’s also great for versatile customization, but because of its rigid nature, it doesn’t support much customization demands as much as chipboard.

Cost

- In terms of cost efficiency, chipboard is more expensive due to its recycling process. It’s not easily derivable, making it more costly than cardboard.

- Cardboard is a natural material often made from paper pulp or virgin wood fibers. It’s widely available, making it an easily accessible and cheaper material.

Key Takeaway

The debate between chipboard vs cardboard doesn’t need to be taken out of proportion. The choice of which to choose largely depends on your specific needs. For instance, if you need a packaging with more strength and durability, cardboard is the best material. On the other hand, if you need packaging that supports a broad range of customization, a chipboard is the best material.

Here at GleePackaging, we craft the best packaging just for you, following your brand and product requirements. Let’s help you create the ideal chipboard or cardboard box to boost your brand visibility and protect your products.